3M recommends replacing both pancake and cartridge filters within six months of opening their packages (PDF), or, in environments where oil aerosols are present, after only 40 hours of total use or 30 days after the first use, whichever comes first. The cartridges are more expensive and weigh far more-8.6 ounces per pair on our scale-but they’re also sturdier, and they might be the better choice if you’ll be doing strenuous physical work, such as a kitchen demolition, while wearing your respirator. The pancake filters weigh just half an ounce per pair, and they’re our first recommendation for typical use outdoors and around the home. NIOSH approval means that, at the equivalent rating (P100 in this case), pancake-style filters, such as the 3M 2097 filter we recommend, protect you just as effectively as hard-plastic cartridge filters like the 3M 60926. They are furnished in a sealed treated paper package.

#Changing gas mask filters series

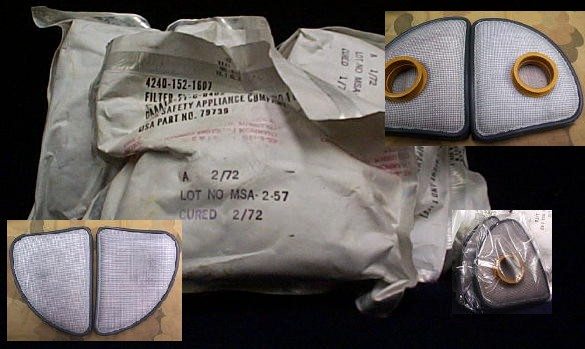

And as P-designated filters, they also protect against oil-based substances in the air, such as paint fumes, as well as some caustic vapors. USGI M13A2 replacement filter element set for the US M17 series gas mask. The “100” designation indicates that they capture 99.97% of fine particulates, such as wildfire smoke. The down-side to this is that, again, it's not as accurate as experimental testing and may therefore result in answers that reflect shorter periods than actually needed because the Advisor Genius uses very conservative parameters for the equation.P100-rated filters are the most widely available kind that meet that criterion. Step 1: Current Program Analysis Step 2: Contaminant Identification Step 3: Respirator/Filter Selection Step 4: Respirator Cartridge and Filter Replacement. OSHA has an Advisor Genius that calculates the estimated contaminant breakthrough time for an activated carbon respirator cartridge taking into consideration physical and environmental factors as well as temperatures.

This is inexpensive and relatively quick. However, the specific information they provide may not match all aspects of your job site and therefore would create a less accurate estimation of cartridge life than experimental testing.ģ. By contacting the company who produces them you may be able to get data related about how their cartridges react to the chemicals on your site. Nobody is going to know the products better than the manufacturer. ago It doesn’t show my filter as an icon in my inventory when I’m wearing it on Xbox like it does on pc. It will swap out the filter on the mask without removing the mask from your face nubswag 6 mo. This will allow your company to make a very precise schedule for replacing spent cartridges.Ģ. Just put a new filter in your hand the hit A on the masks filter in the mask inventory. The lab will be able to determine how long it takes for the specific chemicals on your site to break through the cartridge. Locate a local certified analytical laboratory and have them test the cartridges along with the maximum relative humidity of the work environment. Here are three ways to estimate a cartridge's service life:ġ.

Either way, leave the dangerous atmosphere to fix the mask or replace the cartridges and/or filters.ĭid you know that OSHA now requires employers to provide a respirator cartridge change schedule? If you smell fumes or start tasting dirt through your mask, either your filter or cartridge has been degraded, it has a hole, or your mask is not fitting properly. Even if none of these things happen, it's recommended to dispose of filters after 40 hours of use or 30 days, whichever comes first. The general rule for filter replacement is to leave the contaminated area and dispose of the filter if it becomes damaged, soiled, or breathing becomes difficult.

0 kommentar(er)

0 kommentar(er)